Healthcare and construction is a sensitive confluence. New construction and renovation are necessary to meet the needs of the modern healthcare system and growing hospitals, but it also has to be balanced with making sure the healthcare facilities are performing their critical task: treating patients.

The 1800s and early 1900s proved that the baseline for any healthy society is sanitation. The exponential increase in lifespan and healthy societies can be linked inextricably to the rise of proper sanitation. Taken one step further in healthcare facilities, sterility and maintaining extreme cleanliness is important to all patient outcomes. Avoiding infection during both surgery and the healing process is a mandatory precaution, as it is the largest risk for patients whose bodies are in some way compromised.

Because construction and renovation disrupts operations within healthcare facilities, those disruptions need to be assessed so that they do not in any way contribute risk to patients and healthcare workers. An Infection Control Risk Assessment (ICRA) is a systematic process that determines the level of risk to patients during construction activities and defines controls to reduce that risk.

In this article, we will discuss ICRA protection and how healthcare facilities and construction teams can use modern materials and techniques to conform to defined ICRA controls to keep patients and healthcare staff safe.

Formulating an Infection Control Risk Assessment (ICRA) for Healthcare Construction and Renovation

In order to complete an ICRA for a construction project, the following 4 steps must be taken:

1. Identify the type of construction

2. Identify the patient and/or staff risk group that will be affected

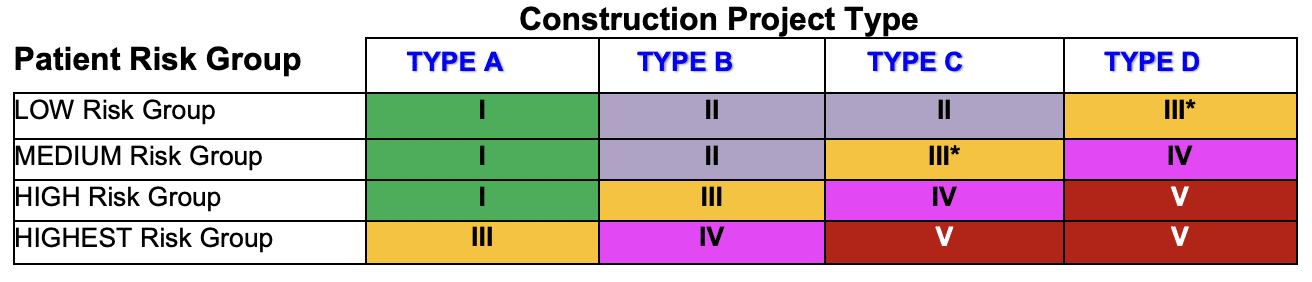

3. Determine the level of infection control classification using the ICRA Matrix

4. Assign necessary controls required to reduce or eliminate risk to patients and/or staff

Step 1 – Identify Construction Type

The type of construction undertaken needs to be identified and can be selected from the following 4 types to use with the ICRA Matrix:

Type A

Type A activities include inspections and/or non-invasive projects such as wall covering installations, removal of ceiling tiles for inspection, minor patch and paint (non-sanding), minor, external plumbing repairs, and related activities.

Type B

Type B activities are small scale projects with short durations that create minimal dust and debris which can be controlled at the source. Examples include above-ceiling installation of cabling and electrical or light fixtures, cutting of walls or ceiling, minor floor repairs, and installing large art or framed pictures.

Type C

Type C activities are work that generates moderate to high levels of dust and debris via demolition such as new wall construction, minor HVAC work, sanding of walls for painting, core drilling operations, major ceiling installations and cable running, and any dust-generating activity that cannot be completed in a single shift.

Type D

Type D activities are major demolition and construction projects, such as work requiring consecutive shifts, heavy demolition that involves the removal of building systems (walls, floors, ceilings, plumbing, HVAC, etc.), and new construction.

Step 2 – Identify Patient and Staff Risk Group

Each healthcare facility is unique and can contain a single type of patient/staff group or multiple of varying complexity, as well as varying environments. For example, sterile processing departments and perioperative departments require severe cleanliness protocols whereas lobbies or waiting areas have far less sensitive protocols. If, for example, the lobby is where construction is taking place, the ICRA will be quite different than if the construction is in or near the sterile processing department.

Step 3 – Determine the Level of Infection Control Classification

The information identified in Step 1 and Step 2 are input into the ICRA Matrix to determine the level of infection control classification most appropriate for the project.

Step 4 – Assigning Appropriate Controls

Once the ICRA Matrix is assessed, the appropriate controls are assigned to reduce or eliminate the identified patient and/or staff risk group. For a detailed understanding of the controls and how to finalize an ICRA permit, see ICRA 2.0.

Relying on Modern Construction Tools and Techniques to Conform to ICRA Protection Protocols

After assessing ICRA protection, it’s clear that the most serious issue affecting healthcare facilities during construction is the potential for the dust and debris generated by activity to “infect” areas that patients and/or staff are in. Not only can dust cause cleanliness issues, it can also contaminate samples, materials, and even harm machines and equipment. Keeping construction dust at bay is critical, and the solution is temporary walls.

Traditional temporary walls are literally walls constructed of drywall and studs to separate construction zones from active areas, to limit dust and debris from going where it shouldn’t. The problem with this traditional method is drywall and studs have to be constructed themselves, which adds to the dust issue, as well as adding labor costs, time, and eventual disposal protocols.

To solve this problem, SwiftWall® has developed a temporary, adjustable wall system perfect for adhering to the requirements of ICRA protection. Instead of having to build a temporary wall from scratch, SwiftWall® temporary wall systems come ready to be pieced together, offering 5x faster installation timeframes.

Importantly for healthcare construction, the SwiftWall® Flex system is a reusable modular panel system that conforms to ICRA Class V requirements by providing negative air capabilities for infection control.

Additional benefits of SwiftWall® Flex include:

- Virtually seamless install: aluminum joiners adhere one panel right into the next

- Closed-cell foam core ensures a non-hygroscopic construction

- Manufactured with non-hygroscopic materials that do not absorb or retain moisture – easy to disinfect with common disinfectants or cleaners

- Available with ASTM E-84 Class A and C flame spread rating

Handle Healthcare Construction and ICRA Protection Controls the Best Way with SwiftWall®

SwiftWall® temporary modular wall systems provide a quick solution for dealing with ICRA in healthcare construction without the headache of building traditional temporary walls from scratch to contain dust.

SwiftWall® systems are easily adaptable and reusable, so they can be quickly taken down and reinstalled once construction phases are complete and moved to other areas, or used for future projects.

Contact our team today to learn more about our temporary wall systems and the complete solution they provide for containing construction dust and debris at healthcare facilities!