Airports are one of the most important elements of the supply chain. As such, they cannot afford to be delayed because of construction.

Although this is a challenging task, construction teams and airport facilities managers can significantly save time and money by using temporary partitions during construction.

The Need for Temporary Partitions During Airport Construction

The traditional technique for temporary walls was to construct actual walls made out of studs and drywall.

While this temporary wall completed its objective at containing dust and maintaining separation between the job site and ongoing airport activity, the walls themselves needed to eventually be removed and discarded.

Though effective, it’s also inefficient—because implementation involves a lengthy construction, installation, tear down, and disposal process

More modern temporary partitions, such as the ones from Swtitwall®, have been crafted to be easy-to store, lightweight, modular, and reusable,which allows construction teams to rapidly install temporary walls and, likewise, rapidly uninstall them.

As a result, airports—the infrastructure of our global supply chain–can continue to operate smoothly with little to no unsightly intervention or disruption.

Benefits of Lightweight Temporary Partition Systems

Modern construction projects are ideally highly optimized in order to save time. However, there are other benefits they have, such as:

1. Flexibility and Mobility

Unlike traditional temporary walls, modern systems are manufactured to be lightweight. This allows even as few as one laborer to erect them. Instead of having to drag heavy materials, modern wall systems can be handled easily due to their lightweight and, furthermore, be arranged without hassle. Additionally, these systems are designed to be flexible and can be readily pieced together no matter the unique space of the job site.

2. Installation Speed

The light weight materials of these temporary walls also means faster installation. Not only can they be carried more but they can be pieced together with minimal effort. Temporary wall systems from SwiftWall®, for example, are able to be installed 5x faster than traditional temporary walls.

3. Minimized Disruptions

Let’s face it: renovation projects are critical to the expansion of an airport’s capabilities, but they cannot disrupt airport operations. Because of their lightweight material and installation speed, modern temporary eliminate almost all disruption to ongoing airport activity.

4. Customization and Design

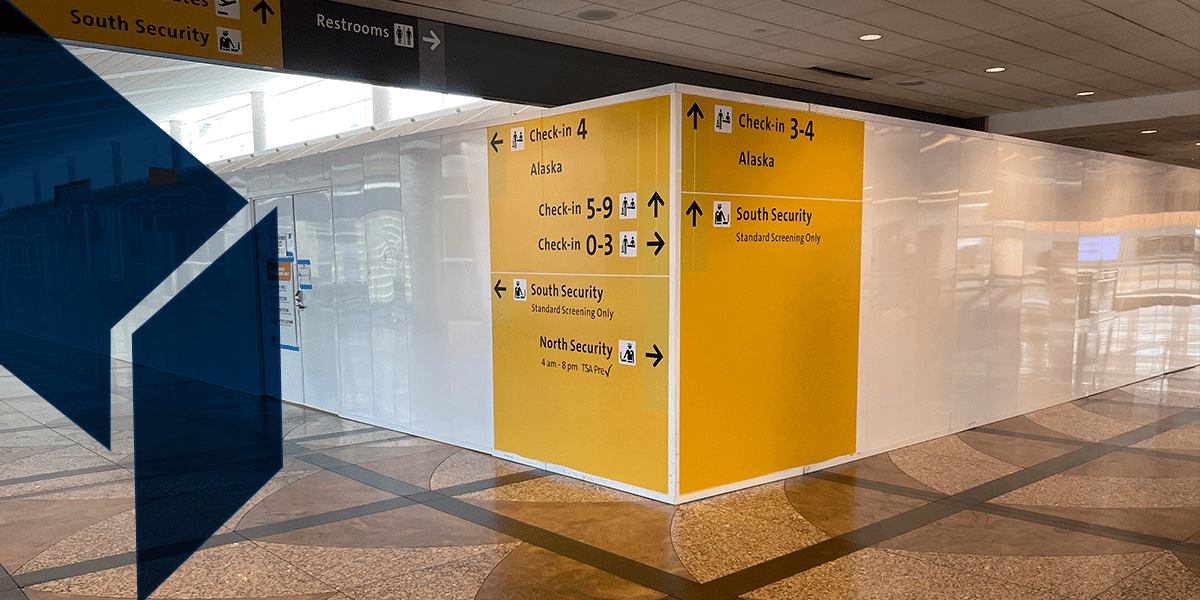

Modern wall systems are not only easier to install and reuse, but they also offer a canvas that can be customized. Especially in airports where signage is key for proper passenger flow, modern wall systems can readily have graphics added so as to not disrupt signage layout. Airports can also use the blank canvas to market specific business in the area.

5. Environmental Concerns

Traditional temporary wall methods involved using raw materials, cutting them to size, and then disposing of them after us. For many airports looking to achieve green energy goals, reusability is a key component, and modern wall systems are built to not only be reusable, but also recyclable at the end of their life cycle.

Lightweight Temporary Wall Partition Systems from SwiftWall®

When it comes to modern temporary wall systems for airport construction and renovation, SwiftWall® offers a line of go-to products that have already helped optimize activity in some of the largest and busiest airports in North America.

Let’s explore a few of our systems:

SwiftWall® Pro

SwiftWall® Pro is SwiftWall’s flagship temporary wall barrier product and a true workhorse. The system offers lightweight yet highly durable panels on a simple track and panel system that installs 5x faster than traditional temporary walls.

The panels are made with a non-hygroscopic ABS with a textured finish on both sides for an elegant, finished appearance. Quickly and easily configured due to the system’s modularity, SwiftWall® Pro also features a STC21 sound rating to keep noise down and a Class C flame spread rating with optional Class A aluminum skins for protection against fire. The system is reusable over 20x, which gives airport facility managers a powerful partition tool to maintain operations and commercial activity.

SwiftWall® Max

For maximum durability for the most intense of construction environments, SwiftWall® offers SwiftWall® Max. The non-porous, non-combustible, weather resistant marine aluminum panels are highly engineered for load-bearing applications, including wind and seismic applications. Even with the added durability, SwiftWall® Max can be installed 3x faster than traditional temporary walls, and is also reusable and readily recycled at the end of its lifespan.

Optimize Your Airport Construction with Temporary Partition Systems from SwiftWall®

Airport construction is a necessity, and keeping airport activity ongoing while it is in progress can be challenging. To achieve these goals, SwiftWall® has manufactured the apex of temporary wall systems, which allows for extremely durable, lightweight barrier walls to be installed quickly and reused many times.

To learn more about SwiftWall® systems and how they can greatly aid in modern airport construction, reach out to our experts today!