When considering the essentials of a construction project, temporary enclosures are not typically high on the list.

In fact, blueprints, protocols, phase design, materials, and labor dominate the process, but as construction gets underway, dust and debris containment becomes a priority—whether planned for or not.

In this article, we’ll discuss using prefabricated temporary wall enclosures for construction and discuss how using these systems leads to an optimized construction process.

Why Temporary Enclosures are Necessary for Construction

Temporary enclosures are essential for a variety of reasons, especially when it comes to construction, though perhaps the most important is debris and dust containment.

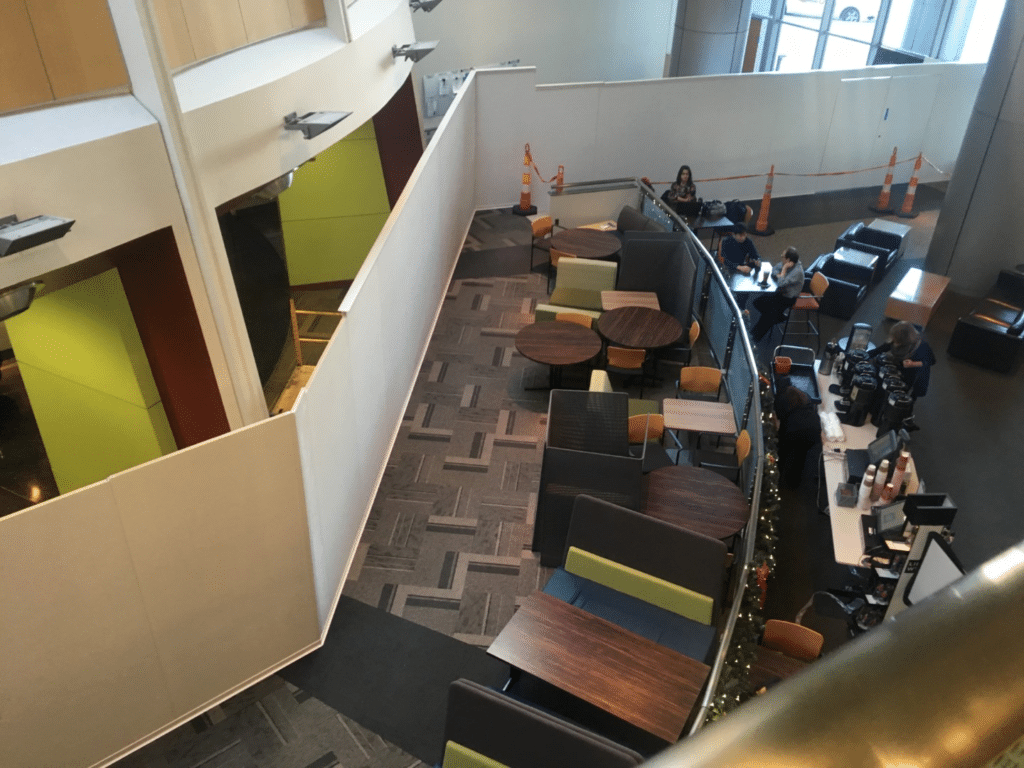

Another reason for having a temporary enclosure during construction revolves around the functionality of the business. Although renovations occur, many places of business stay open accordingly despite undergoing renovations. Temporary wall systems help ensure this happens.

One of the last reasons for using enclosures is to mitigate the noise within the area, especially for guests and those who are still entering the place of business. Construction sites are typically loud, and using temporary enclosures helps contain the sound being spread from the construction.

Traditional Temporary Enclosure Methods

Traditionally, the answer to dust control has been to erect temporary walls with drywall and studs. Although these walls help contain dust, they require more labor to build and, eventually, create more waste for the construction site.

Fortunately, modern materials and manufacturing have led to the creation of temporary enclosures that are both reusable and moveable, which give construction managers a new resource that provides a whole slew of benefits.

SwiftWall® Temporary Walls and Wall Enclosures

SwiftWall solves the issue with traditional construction walls, and they have a line of temporary construction enclosures that massively improve the practices of the old method.

Benefits of SwiftWall® temporary wall enclosure systems:

- Install up to 5x faster than studs and drywall

- Less mess

- Durable and Lightweight

- Stackable

- Graphics Compatible

- Reusable and Sustainable

With temporary wall systems, construction managers can avoid the material and labor costs of traditional drywall and stud systems and, more importantly, integrate temporary enclosure design into the planning phase. Optimization is the name of the game and utilizing temporary wall systems in projects helps eliminate headaches.

Let’s look at the systems offered by SwiftWall®:

SwiftWall® Pro

SwiftWall’s flagship wall system, SwiftWall® Pro installs 5x faster than studs and drywall along a simple track and panel system. The panels are made of non-hygroscopic ABS with a textured finish on both sides of the wall for an elegant, finished appearance.

Although more lightweight thanks to aluminum joiners, SwiftWall® Pro is stronger and more durable than drywall and can be reused 20+ times. Especially useful for renovation settings, the system offers STC21 sound rating to keep noise down. Class C flame spread rating with optional Class A aluminum skins are available as well, and the entire system can be easily recycled when its life-cycle completes.

Multiple standard panel heights of 4, 8, 10, 12 and 16 ft. (by 4 ft. wide) can be stacked to any height to provide flexibility that can be adjusted along project phases. Panels are also available to include windows or doors for tailored needs.

SwiftWall® Flex

SwiftWall® Flex offers all of the benefits of SwiftWall® Pro with the addition of an adjustable height system. Up to 2.75 ft. of adjustment on standard height panels (starting at 7.5, 10, and 12 ft. high) is available, and is easily completed by loosening a bolt and sliding the panels up and down to the required height. It is also available in ASTM E-84 Class A and C flame spread rating,

SwiftWall® Flex offers ICRA Class V adherence and is manufactured with non-hygroscopic materials that do not absorb or retain moisture, the perfect solution for temporary wall systems during construction in healthcare facilities.

SwiftWall® Max

SwiftWall® Max takes temporary wall systems to the next level by offering the ultimate strength and durability for load-bearing applications, such as wind and seismic applications. SwiftWall® Max, installed 3x faster than traditional temporary wall systems, is perfect for high-traffic areas and is able to withstand everyday wear and tear.

Standard panel heights are 8 and 10 ft. by 2 ft. wide with various top and floor mounting options available, as well as optional components like doors and windows. Endless configurations can be created for free-standing structures to weather the most severe of conditions.

SwiftWall® Lite

SwiftWall® Lite offers the fastest, lightest, and most economical wall system from SwiftWall®. Smooth surfaces on both sides with non-hygroscopic expanded PVC skins provide a beautiful, finished appearance that is set along a simple track and panel system.

Even though the most economical, SwitWall® Lite is durable, extremely lightweight, and very easy to handle, and is offered in standard panel heights of 4, 8, 10, 12 and 16 ft. (by 4 ft. wide). The SwiftWall® Lite temporary enclosure system can also be reused multiple times for even more economic benefit.

Upgrade Your Temporary Enclosure Planning and Execution with SwiftWall® Temporary Enclosure Systems

Traditional stud and drywall temporary enclosures work, but they aren’t the end-all-be-all. SwiftWall® temporary wall systems optimize the dust control process on construction sites and they are a new resource that can be reused both during construction and for future projects.

Give our experts a call today and we’ll help select the right system for your needs to further optimize and increase your construction business and projects!