Dust, debris, and the general waste from construction projects is an unavoidable annoyance. The job of contractors and laborers is to fit various types of materials cleanly together into assemblies to form structures.

However, a vast amount of dust is produced by the arrival and movement of materials, the cutting of materials, and the packaging of waste. It, therefore, makes sense when planning a project to take waste and dust into account.

In this article we will discuss methods to reduce construction waste, specifically how recyclable modular walls can be utilized by construction managers and contractors to not only more effectively corral waste created during construction, but also to reduce how much is generated.

5 Ways to Reduce Construction Waste

Thinking about waste on the construction site prior to construction is the best way to control waste. Just like the materials and labor needs for certain aspects of certain

phases are considered, so should the likely waste generated and how to deal with it.

Here are 5 of the most effective ways to reduce construction waste, starting from the planning stage:

1. Prefabrication and Modular Construction

Prefabrication has come a long way and is a massive advantage for many of the most common construction projects. When it comes to waste, prefab materials are exceptional in that the waste generated in their creation happens at the manufacturing center, not the construction site.

2. Waste Management Plan

When developing the plans for the project, coming up with a waste management plan early will dramatically help reduce construction waste. The worst thing that can happen on a job site in terms of waste is for laborers to have trash in hand and ask, “where can I throw this out?” The more times that question is asked, the more waste likely will not make it where it should, and therefore become a problem for later.

Treat a waste management plan just as importantly as the other aspects of construction and a significant reduction in waste will result.

3. Inventory Management

Managing the site’s inventory is an important task that makes sure the right amount of materials are ordered. If mismanaged, more material than necessary may be ordered, or, if a material wasn’t ordered, the kind of order that arrives quickly may be in excess of what is needed simply because of the rapid request. Keep the inventory clean to reduce both headaches and waste.

4. Reuse and Salvage

Incorporating a reuse and salvage aspect to your construction firm is a great way to reduce waste by turning the waste into useful material. If a prior job has material being removed and disposed of, morph the disposal energy into salvage energy and save those materials for use on the new build or a future project. This takes a sharp eye but can be rewarding financially as well as limit waste generation.

5. Lean Construction Practices

Construction is one of the oldest human undertakings and has a lot of preconceived notions, theories, and practices baked in. Even looking at just the last 50 years, sometimes things become ingrained instead of tested. The opportunity to assess each individual project as something new and use teamwork and modern analytical tools to craft an optimized plan can pay huge dividends. As we will see below, opting against traditional methods for modern ones can not only reduce waste, but do so better and more cost-effectively in the long-run.

Dealing with Dust and Debris: Temporary Walls

Traditionally, temporary walls used to contain dust and debris on construction sites. They are indeed effective at containing and confining construction dust as well as separating construction work from ongoing activity, if there is any. The issue with temporary walls is while they may contain dust, they add to the generation of waste. The walls have to be built, meaning there will be stud and drywall cutting waste (not to mention the dust generated by their construction). Furthermore, once construction is completed, the temporary walls must be taken down and disposed of. Temporary walls built with studs and drywall also can’t be readily moved as phases of construction are complete, so additional temporary walls may be built which adds to the growing amount of waste.

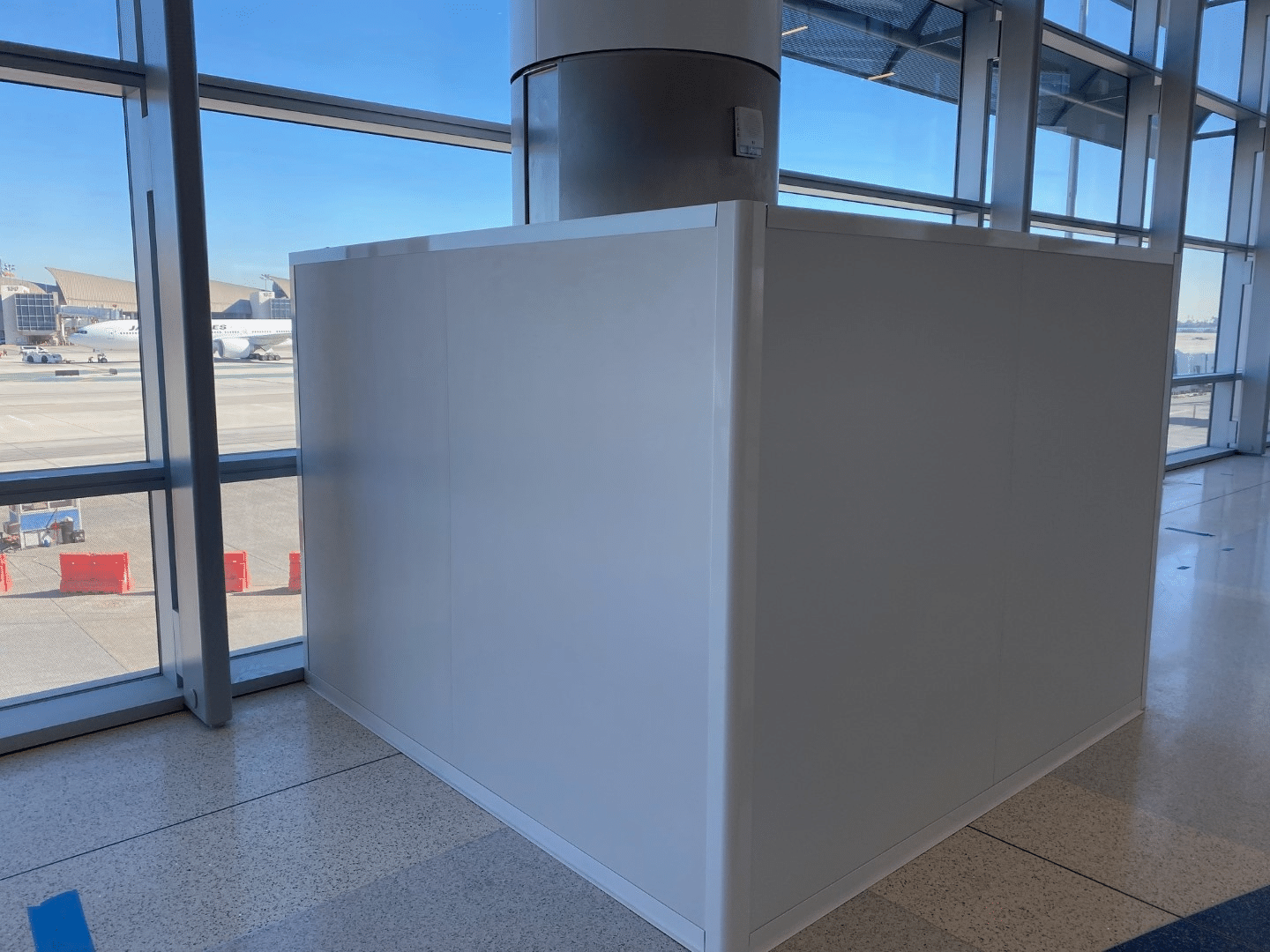

The solution is an elegant one: reusable, modular temporary wall systems. Instead of having to order materials to custom build temporary walls, dispose of the building waste, and then ultimately dispose of the walls themselves when the project completes, temporary wall systems are prefabricated panels that can be swiftly erected and reused efficiently across all phases of construction and even beyond on future projects.

Utilizing Recyclable Temporary Walls to Reduce Waste While Containing Dust

SwiftWall® temporary wall systems give construction managers and contractors a powerful tool that not only more effectively contains dust, it also reduces waste generation on construction sites. Just as important, SwiftWall® systems install up to 5x faster than traditional temporary walls. Since the systems are reusable, the financial implications of utilizing these systems over 5, 10, even 20 projects begins to come into clear focus.

No matter if your project is a new build or a renovation in a structure with ongoing activity, even sensitive activity, SwiftWall® has an array of systems to contain dust and limit waste generation.

SwiftWall® Pro

SwiftWall® Pro is SwiftWall’s flagship product that offers construction managers and contractors the most versatility across projects. A simple track and panel system installs 5x faster than traditional temporary wall systems and comes in 4, 8, 10, 12 and 16 ft. panel heights (by 4 ft. wide). A non-hygroscopic ABS, textured finish is featured on both sides of the wall for an elegant, finished appearance. With an STC21 sound rating and Class C flame spread rating with optional Class A aluminum skins, SwiftWall® Pro is the full package and can be reused over 20 times.

SwiftWall® Flex

When it comes to projects with variable ceiling heights, SwiftWall® Flex is the ideal temporary wall system solution. With a sliding, adjustable height top panel, SwiftWall® Flex offers up to 2.75 ft. of adjustment on standard height panels (starting at 7.5, 10, and 12 ft. high). Manufactured with non-hygroscopic materials that do not absorb nor retain moisture, and available in ASTM E-84 Class A and C flame spread rating, ICRA Class V, SwiftWall® Flex offers a powerful tool in healthcare facility renovations, also installing 5x faster than traditional temporary walls.

SwiftWall® Max

For the pinnacle in stability and durability, the SwiftWall® Max temporary wall system is engineered for load-bearing applications, including wind and seismic applications. Built with non-porous, non-combustible, weather resistant marine aluminum panels, SwiftWall® Max is an excellent choice for high-traffic areas as it is able to withstand everyday wear and tear. Even with its durability and strength aspects, SwiftWall® Max is installed 3x faster than temporary wall systems and is also reusable. Standard panel heights are 8 and 10 ft. by 2 ft. wide.

SwiftWall® Lite

SwiftWall® Lite is a more economical temporary wall system option that retains the core benefits of its product siblings and is even compatible with SwiftWall® Pro. SwiftWall® Lite also installs 5x faster than stud and drywall temporary walls, is extremely lightweight, and suitable for multiple reuses. The Lite version is ideal for projects where cost and efficiency are key concerns.

Reduce Your Construction Waste and Streamline Dust Control with SwiftWall®

Dust and debris can’t be escaped on the construction site, but it can be contained in better ways that don’t generate additional waste. SwiftWall® temporary wall systems provide an elegant modern solution for temporary wall systems that can enhance any project, from new builds to renovation in retail, airport, and healthcare facilities.

Contact our team today to learn more about our game-changing temporary wall systems and we’ll help to find the right product for your specific needs!