Airports are expensive—to say the least—and when it comes to airport construction, they can become even more expensive.

If you’re interested in learning how to reduce construction costs for airports, here are 6 ways you can reduce construction costs and save money while doing it.

6 Ways to Reduce Construction Costs for Airports

1. Value Engineering

It’s not always easy to stay abreast of the latest in material science and use new materials and associated methods when what one knows works and works well.

That said, it’s important to approach every project with the latest and greatest engineered products that maximize the value of the projects and meet the stringent requirements of airports without unnecessary complexity.

2. Efficient Management and Design

Alongside materials, the modern design process is another thing to take note of and integrate as you plan. Using technology and robust planning helps you be on budget and, most importantly, calculate and meet optimized timelines.

From risk management to LEED construction techniques to detailed planning, efficient management of the design process will pay dividends through each phase of airport construction—and for the airport later on down the road.

3. Ideal Site Selection

Another part of efficient management and design is selecting the right site.

The airport construction site needs to be accessible and with minimal environmental impact. This may seem simple, but if there is a need for extensive improvements to achieve accessibility that needs to be done to minimize environmental impact, this could prove to be extremely expensive—and difficult.

By selecting the right site construction site to begin with,severe expenses can be completely avoided.

4. Prefab and Modular Construction

One of the greatest advances in modern construction is prefabricated material and ensuing modular construction.

By ordering materials that are prefabricated and shipped to the site, they can be quickly assembled to significantly reduce labor and the overall timeline.

Integrating prefab materials and modular construction into the design process is a fantastic way to optimize the entire build and keep timelines short.

5. Plan for the Future

If you travel, no doubt you have experienced airport renovation. Passenger and freight air travel continues to burgeon with no signs of stopping, and that means even the largest and busiest airports need to continue to grow.

While anything is possible, it’s much better to take this into consideration at the onset. Planning for eventual expansion can be readily integrated into the design phase without any loss to the overall project.

In fact, doing so in relation to site selection is perhaps the most important thing you can do. It’s important to realize that cost savings aren’t just in the short term, but in the long term. When you craft an excellent plan and deliver with the opportunity for future expansion, everyone wins.

6. Optimized Construction Strategies

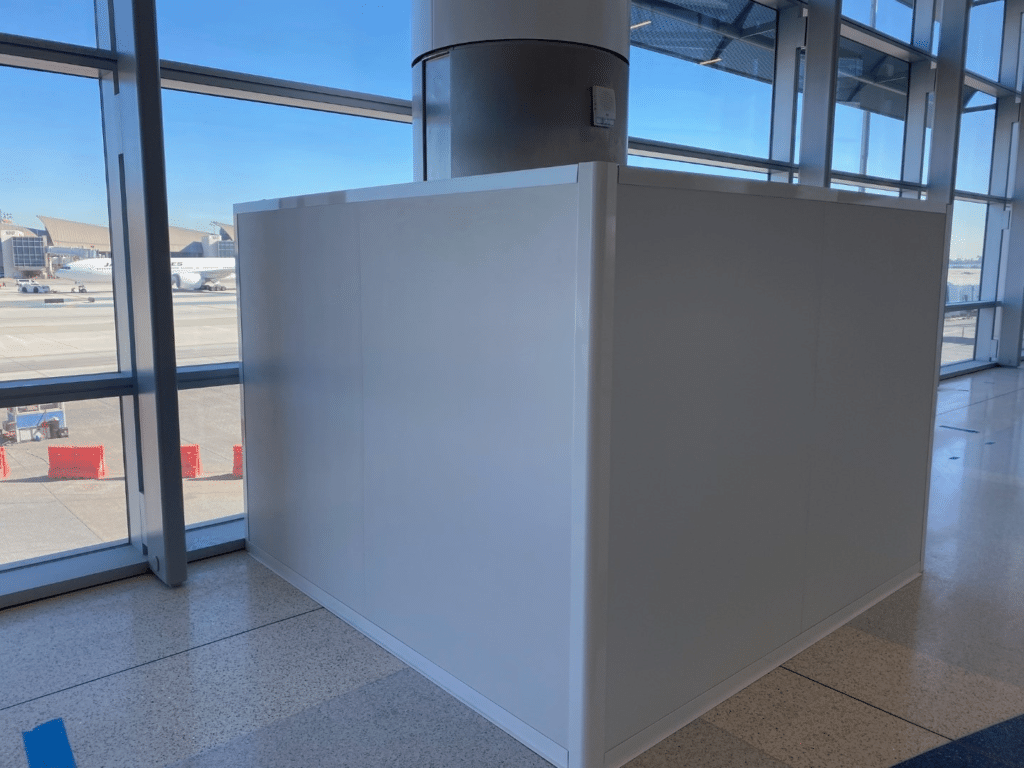

When it comes to learning how to reduce construction costs at an airport, it’s important to look at the entire process to see where other reductions can be made. One of the best and simplest optimized construction strategies is temporary wall systems.

Traditionally, temporary walls were made out of studs and drywall. While they served their purpose of containing dust and confining construction, the material had to be ordered, put together, dismantled, and later disposed of.

That’s a lot of waste of material, time, and labor—and the costs add up.

A fantastic way to optimize this situation is to rely on modern temporary wall systems that are prefabricated and can quickly be installed and reused.

(We’ll talk more about these in the next section.)

How to Reduce Construction Cost With SwiftWall® Temporary Wall Systems

If you’re wanting to learn how to reduce construction costs at airports, another great way to start is by learning about temporary wall systems from SwiftWall®.

Unlike traditional stud and drywall temporary walls, SwiftWall® temporary walls can be installed 5x faster and can be reused over 20 times. Not to mention, they are extremely durable and even offer sound reducing and graphic design capabilities.

Let’s take a look at the two best options for airport construction:

SwiftWall® Pro

SwiftWall® Pro is the flagship product from SwiftWall®, offering contractors and facilities managers an incredibly powerful temporary wall system to keep dust contained and construction separate from active commercial activity when renovating. A simple track and panel system with non-hygroscopic ABS, textured finished on both sides are joined by aluminum joiners for rapid installation.

Although lightweight and easy to handle, SwiftWall® Pro is more durable and offers more strength than drywall. The system features an STC21 sound rating as well as Class C flame spread rating with optional Class A aluminum skins.

The power of SwiftWall® Pro has been a game changer, with some of the largest airports in North America having utilized the product to great success.

SwiftWall® Max

For situations that require even more durability and strength, SwiftWall® Max is the answer. Installing 3x faster than traditional studs and drywall, SwiftWall® Max is highly engineered for load-bearing applications, including wind and seismic applications.

Standard panel heights are 8 and 10 ft by 2 ft wide with optional removable interior panels. Also reusable and ultimately recyclable at the end of its lifecycle, SwiftWall® Max is a great addition to the temporary wall lineup for airport construction that needs added heft.

Work with SwiftWall® to Reduce Construction Costs and Optimize Efficiency

Any way to reduce construction costs, especially with expensive endeavors like airports, is a huge win for both the contractors and ownership.

SwiftWall® temporary wall systems are uniquely positioned to reduce costs by offering a powerful upgrade to traditional temp walls that can be reused and modulated throughout the construction process.

For more information about SwiftWall® and how it has been employed at numerous major airports already, reach out to our team of experts today.