As the backbone of commercial travel for both freight and passengers in the U.S., airports need to be built, renovated, and expanded to meet the needs of the economy.

However, to expand airports effectively—without disruptions—airports need to consider one major thing: dust protection during construction.

The Importance of Dust Protection During Construction

The main concern when it comes to containing dust in construction is to keep it contained so it can be easily cleaned up and removed when the work is complete.

All construction inevitably generates dust and debris, and it’s much better to have it contained than all over the place, which requires both labor and time.

That said, there are other concerns that are also important when construction is happening in an airport, such as:

Safety and Health

Dust particulates may seem benign, but depending on the material, they can be quite hazardous—both to workers and the general public. If construction is occurring in an airport that is continuing its activity throughout the process, the last thing anyone needs is for harmful dust to enter into passenger and staff areas.

Imagine, for instance, a family waiting at a gate for a flight and dust from nearby renovation covering some of the seats. A young child, who doesn’t know any better, might touch the dust and then touch their face or mouth. This is a situation that must be avoided at all costs.

Public Perception

Airports also carry the responsibility of being well-kept for their passengers and staff. Cleanliness is a key factor to aid public perception. If you’re worried about air travel, waiting in a dust-covered airport isn’t going to inspire confidence. In other words, airports need to look pristine, and using proper dust protection during construction can help.

Impact on Equipment

Another factor is having uncontained dust during construction negatively impacting equipment. Airports are filled with extremely important digital and mechanical equipment. Even slight maintenance issues can pose severe slow downs for operations.

Use Temporary Wall Systems For Indoor Construction Dust Control

Thankfully, all of these issues from construction dust can be avoided by employing temporary walls. Traditional temporary walls are constructed from studs and drywall, and they are then torn down and discarded once construction completes. While these types of temp walls are effective at containing and corralling dust, their construction generates dust itself, as well as requiring time and labor to erect.

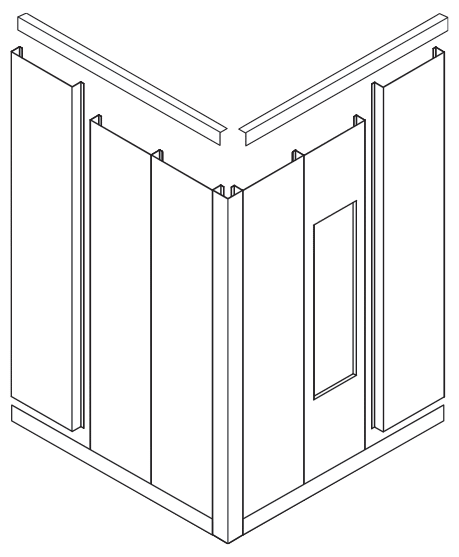

A better solution is to employ modern temporary wall systems that are prefabricated to be even more durable yet more lightweight with a clean, polished finish all the while effectively containing dust and creating separation from airport construction.

Swiftwall®: The Best Solution for Renovation Dust Control

SwiftWall® temporary wall systems are an industry-leading alternative to stud and drywall systems, and they have already proved their worth in some of the country’s largest and busiest airports.

Let’s explore why these systems are designed to provide adequate remodeling dust control and highlight a few other characteristics that can uniquely benefit airports:

SwiftWall® Pro

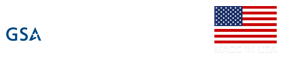

SwiftWall® Pro is the flagship temporary wall system from SwiftWall®, that has been used in airports during interior remodels to meet the exponentially increasing needs of air travel.

SwiftWall® Pro offers lightweight panels that are more durable than drywall and that install 5x faster. Not to mention, the panels have an STC rating of 21 that controls dust during construction but also controls the sound of the construction as well.

Another benefit is that the wall system’s panels have a Class C flame spread rating with optional Class A aluminum skins for safety.

Perhaps most importantly, SwiftWall® Pro is both modular and reusable, which allows the system to be installed and uninstalled readily again and again as construction moves to new phases or for future projects.

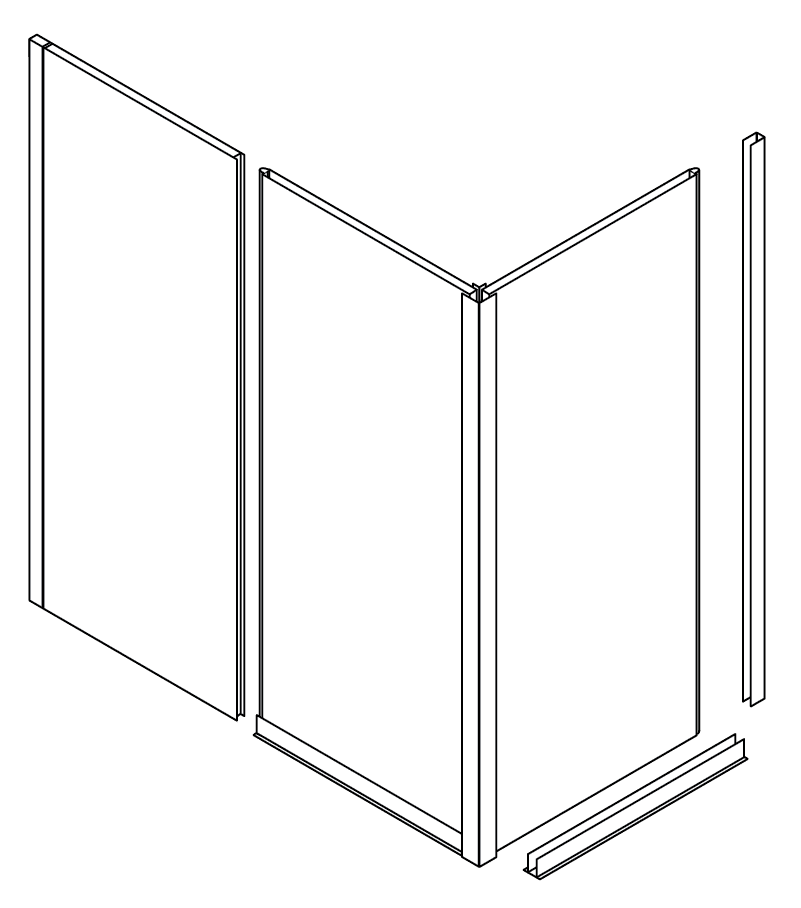

SwiftWall® Max

For the most rigorous demands from a temporary wall system, SwiftWall® offers SwiftWall® Max. The non-porous and non-combustible, weather-resistant marine aluminum panels are engineered for load-bearing applications, including both wind and seismic applications.

Although more durable, SwiftWall® Max are also easy to install, installing 3x faster than traditional stud and drywall assemblies. With standard panel heights of 8 and 10 ft. by 2 ft. wide, SwiftWall® Max is an excellent temporary dust containment system for high-traffic areas in airports that usually contain tall ceilings.

Additional Benefit for Airports with SwiftWall®: Graphics and Advertising Opportunities

Airport walls and ceilings are studded with directions for logistical support for travelers and staff, as well as being a prime location for advertising. When construction is underway and typical locations may be blocked if not deconstructed as part of the renovation process, important signage and advertising opportunities are diminished.

With SwiftWall® temporary wall systems, panels are engineered for graphics, which allows airport operations to use the elegant finish to host signage for directions and as an opportunity for advertising and marketing. Some airports have even utilized the wall space for artwork and interactive displays for passengers to enjoy while they wait for their flights.

Optimize Your Construction Dust Control with SwiftWall®

Controlling dust during construction at airports is a primary concern to keep not only the project underway and optimized, but to prioritize the safety of airport personnel and passengers. SwiftWall® temporary wall systems are the perfect solution to properly contain dust while also providing a modern barrier system to keep construction and ongoing airport activity strictly separated.

To learn more about how SwiftWall® has helped some of the largest airports in the U.S. achieve their renovation and construction goals and the right systems for your project, contact our experts today!