TEMPORARY WALLS FOR MANUFACTURING FACILITIES

Make space conversions quickly and easily with little disruption to operations. Reuse and reconfigure for efficient workflow adjustments. SwiftWall® surpasses conventional temporary wall construction with simpler, faster and cleaner performance.

The Disadvantages of Traditional Approaches

Outdated methods for constructing an industrial manufacturing partition wall have many drawbacks, including:

- Excess waste: Manufacturing companies are increasingly taking steps to reduce their environmental impact. Building with drywall and studs doesn’t support that goal — it creates up to 1 ton of waste for every 70 feet of wall.

- Production disruption: Production is essential to any manufacturing facility’s success and growth. Conventional temporary wall construction can force short-term shutdowns of crucial operations.

- Product contamination: Distributing or manufacturing certain goods demands a clean environment. Traditional solutions generating excess dust or dirt can lead to product loss if not properly contained.

- Ineffective separation: Goods waste can also occur in mixed-use facilities without an effective separation barrier between production lines. Standard methods don’t provide the required protection against product cross-contamination in these settings.

- Health risks: Typical materials like drywall and plywood absorb excess moisture from the air. If the environment becomes too damp, mold and mildew growth can occur and negatively impact your facility’s indoor air quality.

- Safety concerns: Temporary walls that don’t create a barrier between construction and plant personnel can pose injury risks. Approaches like plastic or pipe and drape don’t effectively limit access.

SwiftWall Is the Better Option

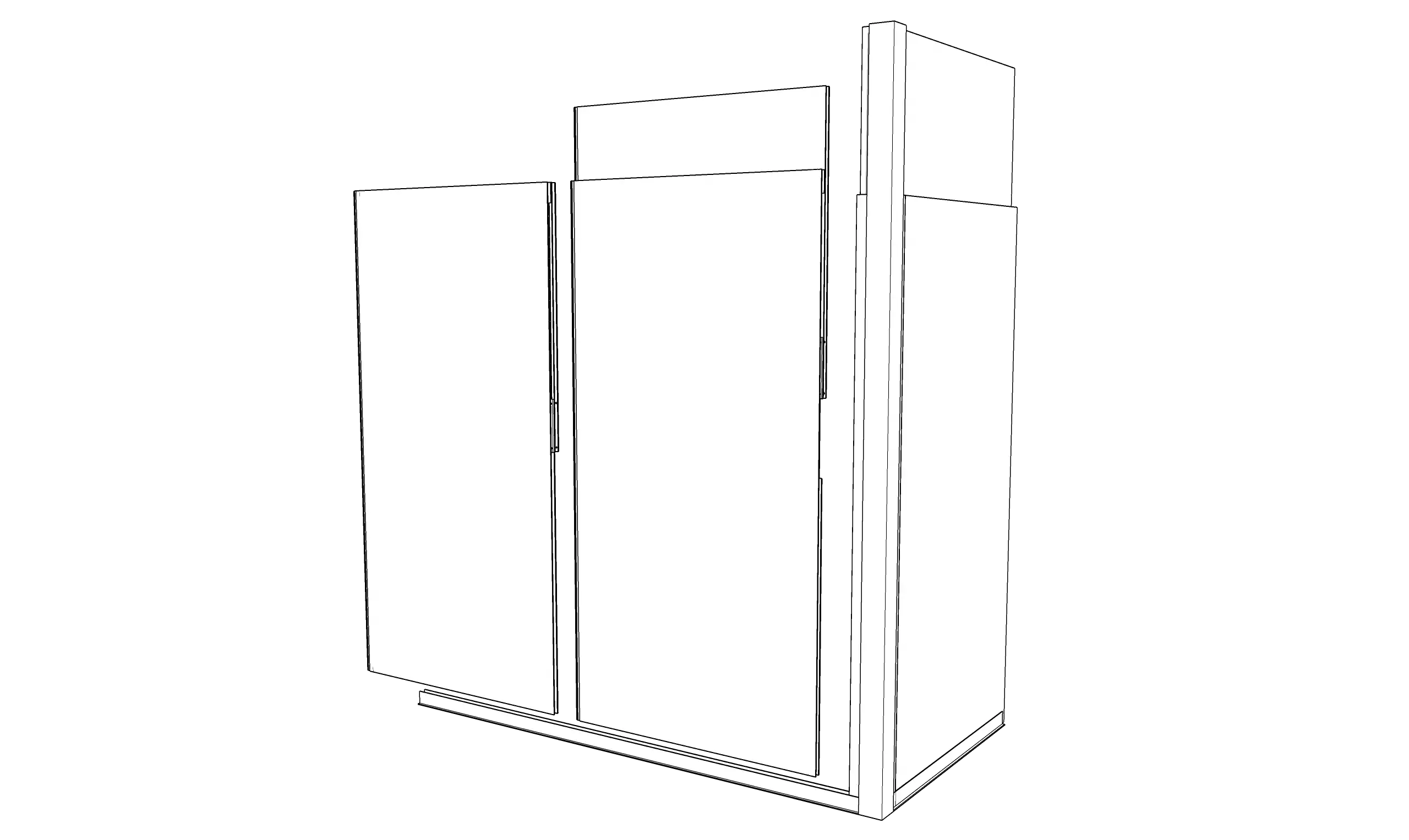

SwiftWall is an adaptable modular wall system offering many benefits for your facility’s temporary needs, including:

- Reusability: You can reinstall our barriers 15 times or more, which helps support your manufacturing company’s environmental, social and corporate governance (ESG) plans.

- Cleanliness: Our solutions effectively contain contaminants and easily wipe clean to help keep your plant compliant with current goods manufacturing practices.

- Speed: Crews can install and reconfigure SwiftWall up to five times quicker than drywall and studs, which means less disruption to your operations.

- Safety: SwiftWall establishes a barrier separating work sites from normal production for increased workplace safety.

- Health: Our prefabricated walls for manufacturing do not absorb moisture and are easy to clean.

See Our Solutions in Commercial Constructions Settings

Explore recent campus projects to see how SwiftWall can help you transform or create spaces.

Get inspired about how SwiftWall can help you reimagine your space or renovate with less noise, dirt and waste.

- 200+ linear ft of 16 ft wall

- Clear panel integration

SwiftWall Pro® provided a packaging staging area for COVID-19 vaccine manufacturing. With the guidance of one SwiftWall technician, three individuals who had never installed SwiftWall were able to install over 200 linear ft in under nine hours. Clear Panels were used to provide more visibility and transparency for government officials visiting the warehouse.

- Pharmaceutical manufacturing plant

- Six phased project

- 500+ linear ft

The major requirement for this project was cleanability. Building a traditional wall where sawing, sanding, painting and eventually demolition are needed was not an option.

SwiftWall Max made up this 16 x 22 ft conference room built inside a manufacturing facility.

REQUEST A QUOTE FOR YOUR NEXT PLANT CONSTRUCTION PROJECT

We’ve been manufacturing temporary walls for industrial facilities since 2014. Our solutions empower plants like yours to quickly and easily create or transform their spaces as needs change. Find a local dealer, or connect with an expert online for a free quote.